< Back to Newsroom

Charging Up: Why Food & Beverage Fleets Have the Most to Gain from Electrification

As the logistics world accelerates toward a zero-emissions future, electrification comes with higher stakes and more moving parts for food and beverage fleets hauling perishable goods. And yet, despite the added complexity, this sector stands to benefit more than most.

Apr 24 2025 | 7 min read

As the logistics world accelerates toward a zero-emissions future, food and beverage fleets sit at a unique—and often overlooked—crossroads. The pressure is on to decarbonize, but for fleets hauling perishable goods, electrification comes with higher stakes and more moving parts. And yet, despite the added complexity, this sector stands to benefit more than most.

That’s why we’re proud to sponsor the “Food and Beverage Sector: Transforming Logistics for Greater Efficiency” session at this year’s ACT Expo. Join us to hear from fleet leaders including Martin Brower‘s Danny Fahey, Manhattan Beer Distributors‘ Juan Corcino, US Foods‘ Ken Marko and UNFI‘s Nick Selders who already making the switch, and learn how thoughtful strategy and the right infrastructure can unlock both economic and environmental wins.

Here’s a preview of why MN8 Energy sees the food and beverage sector as one of the most critical—and promising—segments in fleet electrification.

Reliability is Critical for Cold Chain Operations

Food and beverage (F&B) logistics is a high-energy game. Whether it’s chilled beverages, imported produce or frozen meats, transportation refrigeration units (TRUs) are constantly drawing power—at the depot and on the move. Power loss at any point along the way can spoil freight or threaten food safety, making resiliency a top priority.

Electric TRUs (eTRUs) offer a powerful alternative to traditional diesel TRUs, cutting both emissions and diesel use, but they must be deployed with care. Electrifying the cold chain comes with added complexity. TRUs need reliable access to power while trucks are on the road, during loading, and even while sitting in the yard. That means charging infrastructure must do more than just supply energy—it must ensure uptime through integrated systems like battery storage, on-site solar to pick up the slack when the grid can’t.

MN8’s turnkey model bakes in that integration and the resilience it offers from day one —through optional microgrids, backup generation, and design strategies that protect product integrity under all conditions. We help fleets design and finance electrification plans that match operational realities—not just sustainability aspirations.

One Industry, Many Fleet Profiles

Sure, many F&B companies run Class 8 tractors for long hauls. But that’s not the whole story. Regional distribution and last-mile delivery play an equally important role in the food supply chain, served with different vehicle classes that can bring very different charging needs.

The weight and load profiles of food and beverage trucks can vary dramatically—from heavy beverages to light packaged snacks—affecting range, energy use, and overall infrastructure planning. A one-size-fits-all approach doesn’t work here.

Consider the Hunts Point Food Distribution Center in New York City. On any given day, more than 15,000 trucks pass through the market—but they’re far from uniform. Roughly 5,000 are Class 8 tractors, 6,000 are box trucks, and 4,000 are smaller Class 2–3 vehicles. Together, they serve a range of delivery functions—from hauling bulk produce and meat to distributing seafood and packaged goods—supplying restaurants, bodegas, grocery stores, and institutions for over 22 million people in the region. Each vehicle class comes with different operational patterns, duty cycles, and infrastructure needs—making Hunts Point a microcosm of the food and beverage industry’s electrification challenge.

At MN8, we help fleets navigate this complexity. From behind-the-fence depots for return-to-base vehicles to shared hubs for operators who need flexibility, our Charging Infrastructure as a Service (CIaaS) model is designed for scale to accommodate a wide range of needs. We match infrastructure to duty cycle, vehicle class, and shift schedule—not the other way around.

Why the Right Plan—and Partner—Matters

Electrifying food and beverage fleets requires a different level of planning. It’s not just about plugging in trucks—it’s about designing infrastructure that can:

- Handle variable loads and peak demand,

- Integrate eTRUs into existing logistics flows,

- Provide resilience against outages, and

- Help meet strict regulatory and emissions targets.

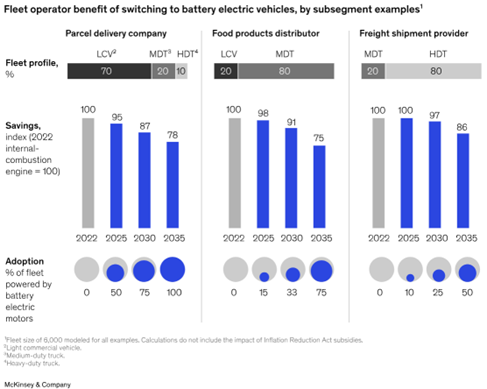

But the upside is clear. According to McKinsey, Medium & Heavy Duty (MHD) electric vehicles have already reached total cost of ownership (TCO) parity with diesel in segments like parcel delivery and food products, with full-truckload applications not far behind. That means if you get it right, electrification isn’t just a sustainability win—it’s an economic one too.

At MN8, we don’t ask you to figure this out alone. Our CIaaS model delivers turnkey infrastructure with no upfront CapEx, and is managed by a team with deep experience in EV charging, solar, and batteries.

So whether you’re just starting your electrification journey or scaling up across regions, we’re ready to help you move fast—without compromising freshness or financials.

Let’s Talk at ACT Expo

Swing by our booth or catch us at the “Food and Beverage Sector: Transforming Logistics for Greater Efficiency” panel to hear how leading fleets are doing it today. We’re excited to showcase how electrification and charging infrastructure can become a strategic asset—not as well a means for achieving sustainability targets—for food and beverage logistics.

Want to learn more now? Reach out to us at [email protected].

Coming Up Next: Co-Located Shared Hubs on Your Own Property

In our next post, we’ll explore what happens when a fleet owns its real estate and wants to convert it into a revenue-generating asset. Co-located shared hubs combine the best of both worlds—charging for your own trucks, and shared infrastructure that other fleets can use too. Spoiler alert: it’s a win-win.